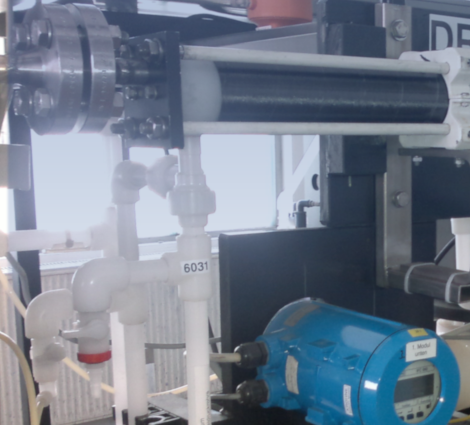

| Pilot plant KLARA

With the KLARA pilot plant, pilot tests can be carried out on site with up to two 8" winding modules. The maximum operating pressure is 40 bar. Furthermore, a modular extension of the plant with a ceramic loop is possible. The plant is fully automated and equipped with a rinsing tank, which is also used as a storage tank. A direct connection of the plant to a on-site feed tank is possible. The plant is operated via a panel PC in the control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network.

|

|

Technical data:

| Process: |

|

||||||||

| Maximum Pressure: | 40 bar | ||||||||

| Membrantyp: | 8" spiral wound element 2 pc. - Convertible to ceramic 2 x 7 pc. | ||||||||

| Pre-filtration: | 1 µm - 25 µm | ||||||||

| Tank: | 250 Liter designed as pressure tank | ||||||||

| Material: | V4A / EPDM | ||||||||

| Installed pump capacity: | approx. 8 kW | ||||||||

| Power supply: | 32 A 400V | ||||||||

| Dimensions (LxWxH): | 4000 x 1250 x 2180 [mm] |

|

|

Pilot plant JULIA With the pilot plant JULIA pilot tests can be carried out on site with up to two 8" winding modules. The maximum operating pressure is 40 bar. . The plant is fully automated and equipped with a rinsing tank, which is also used as a storage tank. A direct connection of the plant to a on-site feed tank is possible. The plant is operated via a panel PC in the control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network. |

Technical data:

| Process: |

|

||||

| Maximum Pressure: | 40 bar | ||||

| Membrane type: | 8" spiral wound element 2 pc. | ||||

| Pre-filtration: | 1 µm - 25 µm | ||||

| Tank: | 400 Liter | ||||

| Material: | V4A / EPDM | ||||

| Installed pump capacity: | approx. 8 kW | ||||

| Power supply: | 32 A 400V | ||||

| Dimensions (LxWxH): | 4000 x 1250 x 2180 [mm] |

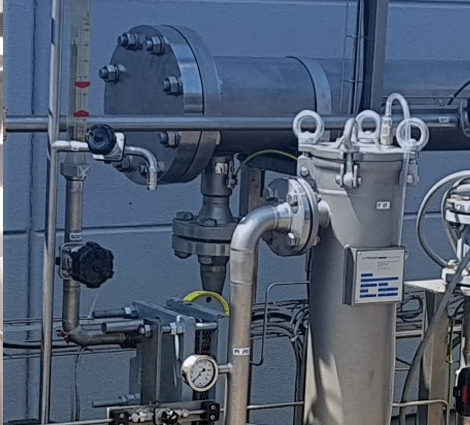

| Pilot plant PIA-2

The pilot plant PIA-2 is designed for high pressure reverse chromosis experiments. Pilot tests can be carried out on site with an 8" winding module. The maximum operating pressure is 120 bar. The plant is fully automated and equipped with a rinsing tank, which is also used as a storage tank. A direct connection of the plant to a on-site feed tank is possible. The plant is operated via a panel PC in the control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network. |

|

Technical data:

| Process: |

|

||||||

| Maximum Pressure: | 120 bar | ||||||

| Membrane type: | 8" spiral wound element 1 pc. | ||||||

| Pre-filtration: | 1 - 25 µm | ||||||

| Tank: | 250 Liter designed as pressure tank | ||||||

| Material: | V4A / EPDM | ||||||

| Installed pump capacity: | approx. 14 kW | ||||||

| Power supply: | 32A 400V | ||||||

| Dimensions (LxWxH): | 4000 x 1250 x 2200 [mm] |

|

|

Pilot plant OLIVIA The pilot plant OLIVIA is designed for the performance of experiments with ceramic membranes. On site, pilot tests can be carried out with two serial ceramic pressure tubes with different diameters. In addition, the pilot plant can be extended with an additional ceramic loop. The plant is fully automated and equipped with a rinsing tank, which is also used as a storage tank. A direct connection of the plant to a on-site feed tank is possible. The plant is operated via a panel PC in the control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network. |

Technical data:

| Process: |

|

||||||

| Maximum Pressure: | 10 bar | ||||||

| Membran type: |

Ceramic 2 x 1 pc. - Expandable to ceramic 2 x 7 pc. |

||||||

| Anzahl an Elemente: | 2 pc. | ||||||

| Pre-filtration: |

1 - 400 µm |

||||||

| Vorlage / Spültank: | 250 Liter | ||||||

| Material: | V4A / EPDM | ||||||

| Installierte Pumpenleistung | approx. 6 kW | ||||||

| Power supply: | 63 A 400V | ||||||

| Abmessungen (LxBxH): | 2650 x 1050 x 2350 [mm] |

| Pilot plant MINI-OLIVIA

With the MINI-OLIVIA pilot plant, pilot tests can be carried out on site with up to two parallel ceramic pressure tubes. The maximum operating pressure is 10 bar. The plant is operated manually. The plant is switched on at the control cabinet. Temperature, pressure and flow rates are displayed directly on the sensor.

|

|

Technical data:

| Process: |

|

||||||

| Maximum Pressure: | 7,5 bar | ||||||

| Membrane type: | Keramik 1 pc. | ||||||

| Pre-filtration: | 1 - 200 µm | ||||||

| Tank: | 30 Liter | ||||||

| Material: | V4A / EPDM / PVC | ||||||

| Installed pump capacity: | 2,2 kW | ||||||

| Power supply: | 16A 400V | ||||||

| Dimensions (LxWxH): | 1400 x 500 x 1930 [mm] |

|

|

Pilot plant SALINA The Salina pilot plant is designed to carry out nano- and reverse osmosis experiments with upstream microfiltration. The Salina is designed to be acid-proof, so that even experiments with highly corrosive media such as HCl can be carried out. The plant is fully automated. The plant is operated via a panel PC in the control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network. |

Technical data:

| Process: |

|

||||||||

| Maximum Pressure: | 80 bar | ||||||||

| Membrane type: | 2,5" spiral wound element 1 pc. - Rohrmodul 1 pc. | ||||||||

| Pre-filtration: | 1 - 400 µm | ||||||||

| Tank: | 150 Liter | ||||||||

| Material: | Hastelloy, PP | ||||||||

| Installed pump capacity: | 16 kW | ||||||||

| Power supply: | 63A 400V | ||||||||

| Dimensions (LxWxH): | 4020 x 2050 x 2000 [mm] |

| Pilot plant Container UF/UO

With the container UF/UO, pilot tests can be carried out on site with complete pre-filtration, ultra-filtration and reverse osmosis. Two ultrafiltration modules can be operated in parallel, which makes the plant ideal for comparing different UF modules. This makes the plant ideal for piloting surface water and pre-treated wastewater. The plant is fully automated and equipped with all necessary components such as feed tank, CIP and chemical dosing stations. The plant is operated via a panel PC in a control cabinet mounted on the plant. The analog values (conductivity, pH, pressure, flow rates and temperature) are recorded by the integrated data acquisition and can be read out via USB or an Ethernet interface. In addition, the plant can be equipped with remote access via a mobile network.

|

|

Technical data:

| Process: |

|

||||||||

| Maximum Pressure: | 5 bar (UF) - 25 bar (UO) | ||||||||

| Membrane type: | Ultrafiltration module 2 St - 8" spiral wound module 2 pc. | ||||||||

| Pre-filtration: | 1 - 400 µm | ||||||||

| Tanks | working tank: 350l - filtrate tank: 1000l | ||||||||

| Material: | 1.4571 / PP | ||||||||

| Installed pump capacity: | approx. 19 kW | ||||||||

| Power supply: | 63 A 400V | ||||||||

| Dimensions (LxWxH): | 6095 x 2440 x 2890 [mm]; 20" High-Cube Seecontainer |