|

Microfiltration |

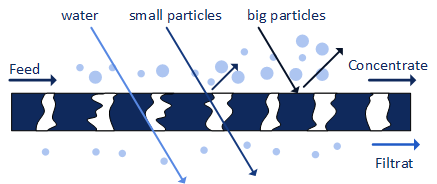

Microfiltration is a pressure operated membrane process in which solid, colloidal and emulsified particles with a separation limit of 10 - 0.1 µm are separated from a liquid. Smaller particles below the separation limit pass the membrane.

|

|

The process follows the principle of classical filtration through pores. The transport of substances and fluids through the pores takes place by convective transport. Diffusion transport, which forms the basis for nanofiltration and reverse osmosis, plays a subordinate role in this process.

Our typical applications for microfiltration are:

- Removal of colloidal substances from acids and alkalis

- The treatment of process liquids by separating e.g. hydroxides, lime particles, abrasive particles and catalysts

- Concentration of suspensions

- Separation of sludge

Separate the best from the rest - Individual process combinations for highest efficiency

Microfiltration is often used as a preliminary stage in an overall process. The filtrate can be further treated in subsequent process steps and thus often be returned to the process. Also the concentrate, if it contains valuable substances, can often be profitably reused due to the high concentration. Thus it is possible for us to get the maximum out of your process and avoid waste water by an intelligent process control (Minimum Liquid Discharge / MLD ; Zero Liquid Discharge / ZLD).

The right support in every stage of the project

We have gained experience with a variety of different process fluids. We would be pleased to assist you as a plant engineering company in the selection of the suitable membrane and the optimal process control! For special applications, we are also happy to offer you the possibility of process screening in our laboratory with subsequent industrial piloting as part of our 4 steps 2 separation!