|

Nanofiltration |

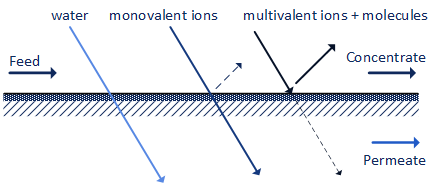

Nanofiltration is a pressure-operated membrane process in which the smallest molecules and multivalent ions are separated from a solution. Monovalent ions like Na+ or Cl- pass the membrane almost completely.

|

|

Nanofiltration works like reverse osmosis using a dense membrane via transport by diffusion. Nanofiltration is distinguished by a membrane structure which is more permeable for monovalent ions than for bivalent ions. In addition, some of the nanofiltration membranes available on the market differ considerably with regard to their separation limit. By selecting suitable membranes, a selective separation of undesirable substances is possible.

Our typical applications for nanofiltration are:

- Cleaning of caustic solutions in the pulp and food industry

- Purification of acids by selective separation of metals

- Desalination of solutions

- Separation of multivalent ions (phosphate, sulfate, calcium, magnesium)

- Concentration of process solutions

- Separation from COD

- Decolorization of solutions

Separate the best from the rest - ndividual process combinations for highest efficiency

Nanofiltration is a very adaptable process that enables a selective separation of ingredients. Further process steps after nanofiltration are also possible. The concentrate can be further concentrated in the following process steps, e.g. by high-pressure reverse osmosis, and thus be reused as a profitable raw material. The filtrate can be further processed, e.g. by a downstream reverse osmosis, to deionised water, which is returned to the process. Thus it is possible for us to get the maximum out of your process and avoid waste water by an intelligent process control (Minimum Liquid Discharge / MLD ; Zero Liquid Discharge / ZLD).

The right support in every stage of the project

We have gained experience with a variety of different process fluids. We would be pleased to assist you as a plant engineering company in the selection of the suitable membrane and the optimal process control! For special applications, we are also happy to offer you the possibility of process screening in our laboratory with subsequent industrial piloting as part of our 4 steps 2 separation!