|

Membrane Degassing |

Membrane degassing is a non-thermal process which is primarily used for the removal of dissolved carbon dioxide and/or oxygen.

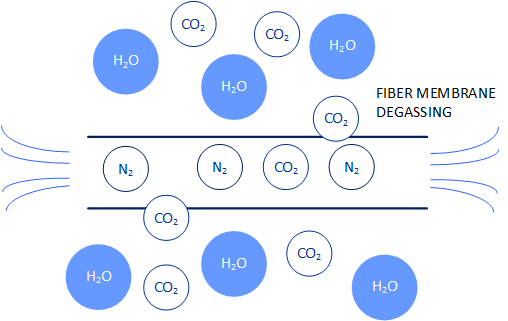

For membrane degassing, hydrophobic pore membranes are used which are impermeable to water. Gases on the other hand can pass through the membrane. For this purpose, hollow fibre modules are usually used, which have a high packing density. The water to be degassed is led lengthwise past the fibres.

|

|

Due to the partial pressure the gas diffuses through the membrane. The water, however, is retained by the hydrophobic surface of the membrane. To generate the necessary partial pressure gradient, either a vacuum can be applied or strip gas (nitrogen, ultrapure air) is used, which is continuously conveyed in the hollow fibres and thus removes the removed gas.

Our typical applications for membrane degassing are:

- Removal of carbon dioxide from water

- Removal of oxygen from water for e.g. district heating

- pH value increase through deacidification

Separate the best from the rest - Individual process combinations for highest efficiency

Membrane degassing is often used before mixed bed ion exchangers for complete desalination or anion exchangers. This enables CO2 to be effectively separated, which considerably extends the service life of the ion exchanger and saves regeneration chemicals. Further fields of application are the removal of oxygen. Here, the advantages of membrane degassing compared to other processes are low energy consumption, low operating costs of a compact design and reliable and continuous operation.

The right support in every stage of the project

We have gained experience with a variety of different process fluids. We would be pleased to assist you as a plant engineering company in the selection of the suitable membrane and the optimal process control! For special applications, we are also happy to offer you the possibility of process screening in our laboratory with subsequent industrial piloting as part of our 4 steps 2 separation!